The higher proportion of sp3 bonds results in:

- higher density,

- higher hardness (at room temperature and elevated temperature),

- thermal stability,

- oxidation resistance,

- higher residual stress and

- higher thermal conductivity.

This characteristic leads to special properties and application possibilities:

- Smooth surface

- High mechanical hardness

- Chemical resistance

- Low coefficient of friction between tool and workpiece

- Good corrosion resistance

- Non-reflective surface

- Suitability for biocompatible products

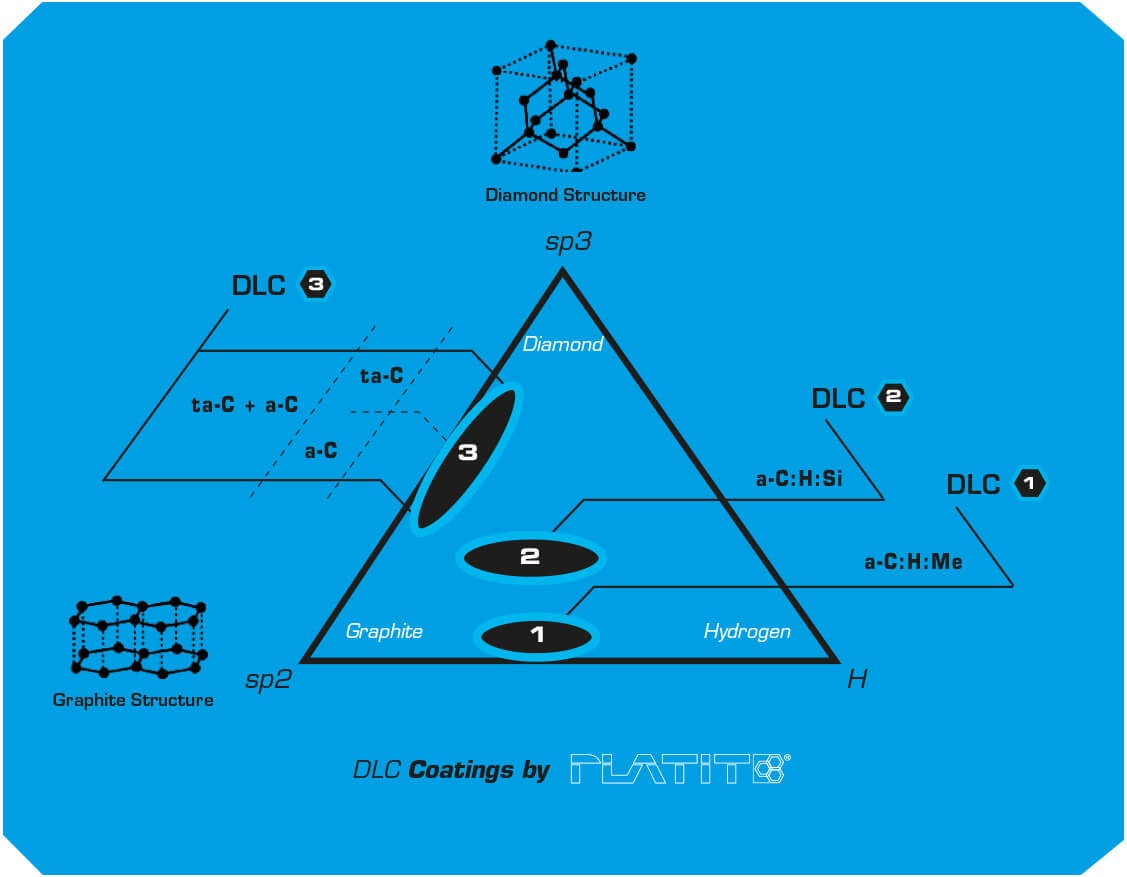

Categories of DLC coatings

- a-C = Hydrogen-free amorphous carbon

- ta-C = Tetrahedrally-bonded hydrogen-free amorphous carbon

- a-C:Me = Metal-doped hydrogen-free amorphous carbon

(Me = Ti) - a-C:H = Amorphous carbon with hydrogen

- ta-C:H = Tetrahedrally-bonded amorphous carbon with hydrogen

- a-C:H:Si = Si-doped amorphous carbon with hydrogen

- a-C:H:Me = Metal-doped amorphous carbon with hydrogen

(Me = W, Ti)

Comparison of the main properties of PLATIT DLC coatings

DLC1

DLC2

DLC3

PLATIT coating unit

Pi111,

Pi411,

PL1011Pi411,

PL711,

PL1011Pi411

Composition

a-C:H:Me

a-C:H:Si

ta-C + a-C

(over 50% ta-C)Process

Arc in C2H2 atmosphere

PECVD

Sputtering

Coating architecture

As top layer

As stand-alone or as top layer

As stand-alone

Doping

Ti or Cr

Si

None

Coating thickness [µm]

< 1

< 3

0.3 - 1

Young’s modulus [GPa]

200

250

350 - 450

Nano-hardness [GPa]

< 20

> 25

35 - 55

Roughness

Ra ~ 0.1 µm

Rz ~ coating thicknessRa ~ 0.03 µm

Rz ~ coating thicknessRa ~ 0.06 µm

Rz ~ coating thicknessCoefficient of friction [μ]

PoD (at RT, 50 % humidity)0.15

0.1 - 0.2

0.1

Max. service temperature [°C]

400

400

450

Coating temperature [°C]

< 400

< 220

< 100

Main application

Improvement of the run-in process of a tool, lubrication by formation of transfer films

Components, punches and dies

Tools

Would you like to learn more?

Please click on the following links: